Overmolding

Nov21,2022

Overmolding is the injection molding process where one material (usually a soft plastic like TPE TPU or TPR) is molded onto a second material (typically a rigid plastic like PP or ABS).

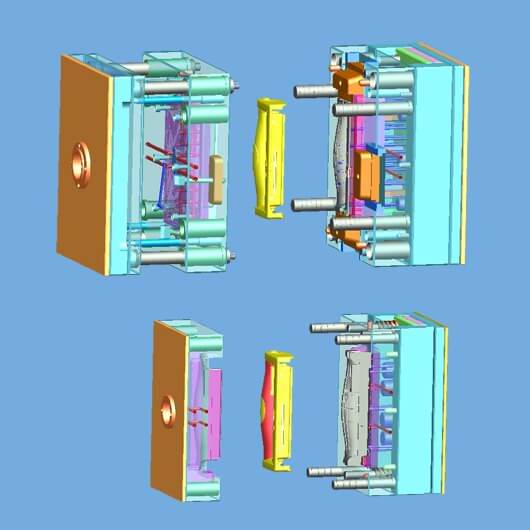

First, a base component is molded from one mold. Then, a second layer is molded directly on top of the first by another mold to create a single solid piece. Overmolding is commonly used to manufacture rigid plastic parts that feature a rubber soft handle. The two-shot process of overmolding a toothbrush, for example, consists of forming a base layer for the plastic handle and a top layer of rubber (to make the toothbrush less slippery and more comfortable to hold).

Overmolding is used across lots of industries and serves a wide array of applications:

1, Grip – Generally speaking, components with handles often need something to help the operator maintain grip, especially in wet conditions.

2, Vibration Dampening – Softer rubber-like bumpers can protect components (like electronics) from vibrations.

3, Comfort – Since the grip material is injection overmolded, it can be formed in any shape, making it great for ergonomics. Most importantly, overmolded soft material protects your hands.

4, Sealing – Create water-resistant seals on electronics and other devices.

5, Sound Absorption – Sound waves can be absorbed by overmolded layer.

6, Foldable – Not only more colors can be realized in one product, but also soft overmolded areas can be folded to save space for shipping or storage.

When selecting material, both the substrate and the overmolded material should be considered. Before you start the molds, you need to make sure which and which can adhere well to each other.

Below are some factors to consider:

1, Bonding – Some Materials will bond together when overmolded, and some won't. A complete bond is the ideal situation, although it is not always necessary. If the materials can't bond together or don't need to, mechanical features like undercuts and indents can be designed to ensure a long-lasting connection.

2, Temperature – Since you are molding plastic over plastic, the base component must not deform under the heat and pressure of the injection molding process.

Insert molding and overmolding are both processes for using the injection molding process to mold plastic onto something. The key difference is that overmolding is typically molding a rubber-like soft plastic over the top of another rigid or hard plastic component, while insert molding involves molding plastic around a non-plastic(usually metal like brass or stainless steel or aluminum) component.

<< Previous page

Next page >>